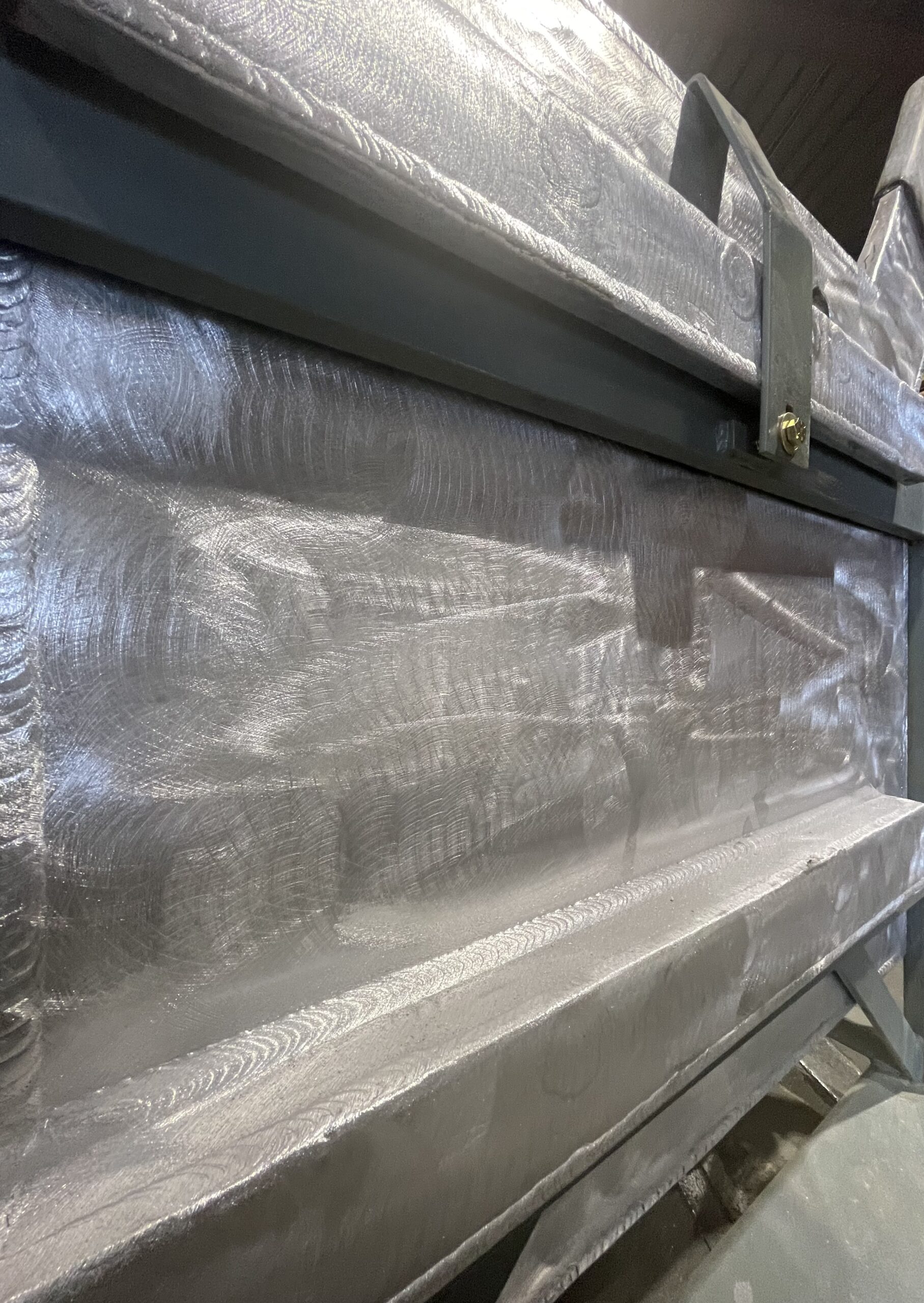

To maintain proper working condition and usage of various metals, pickling is frequently needed in order to remove oxidization and...

The highly-corrosive environments frequently found in the smelting and refining industries benefit from the corrosion-resistant properties of lead. Lining tanks...

On the market today, lead flashing is considered a durable weatherproofing material for use in construction and roofing projects. Its...

The greatest natural threat to the structural integrity of a marine vessel’s hull is corrosion, but a well-selected anode is...

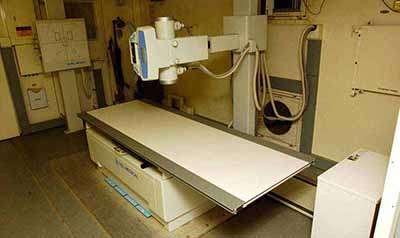

For the highest level of protection against x-ray and gamma radiation, the hospital, veterinary and medical fields look to sheet...

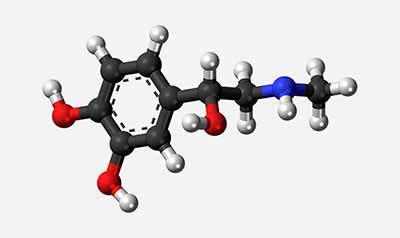

The electroplating industry has complex and varied requirements. To help protect from corrosion and contamination, the lead lining of tanks...